Challenge Courses Good Practice Guide

Guidance for high and low challenge (ropes) courses and adventure/initiative games.

Version 1.0 | Date 23 Sept 2019 | Details: Version one release.

Acknowledgment, disclaimer and preface

Acknowledgment, disclaimer and preface

Traditional owner acknowledgement

The Outdoor Council of Australia and the Australian AAS Steering Committee would respectfully like to acknowledge the Traditional Owners, their Elders past, present and emerging, for the important role Indigenous people continue to play in Australia and most especially on the land and waters used for outdoor activities and recreation.

Disclaimer

Copyright

Copyright 2019 Outdoor Council of Australia.

Disclaimer

The information published in the Australian Adventure Activity Standard (AAAS) and accompanying Good Practice Guides (GPG’s), including this document, is for information purposes only and is not a substitute for, or intended to replace, independent, professional or legal advice. The information contained in the Australian Adventure Activity Standard and the Good Practice Guides are a guide only. Activity providers and any other person accessing the documentation should consider the need to obtain any appropriate professional advice relevant to their own particular circumstances, including the specific adventure activities and needs of the dependent participants.

The information published in the Australian Adventure Activity Standard and Good Practice Guides are subject to change from time to time. Outdoor Council of Australia gives no warranty that the information is current, correct or complete and is not a definitive statement of procedures. Outdoor Council of Australia reserves the right to vary the content of the Australian Adventure Activity Standard and/or Good Practice Guides as and when required. Activity providers should make independent inquiries as to the correctness and currency of the content and use their own skill and care with respect to their use of the information.

The Australian Adventure Activity Standard and Good Practice Guides do not replace any statutory requirements under any relevant State and Territory legislation and are made available on the express condition that Outdoor Council of Australia together with the authors, consultants, advisers and the Australian Adventure Activity Standard Steering Committee members who assisted in compiling, drafting and ratifying the documents:

- are not providing professional or legal advice to any person or organisation; and

- are not liable for any loss resulting from an action taken or reliance made on any information or material contained within the Australian Adventure Activity Standard, Good Practice Guides and associated documents.

Preface

Forward

“Adventure is worthwhile” – Aristotle

The Australian Adventure Activity Standard and Good Practice Guides are designed to ensure effective, responsible, sustainable and safe delivery of adventure activities to dependent participants. They can help people across the outdoor sector to develop appropriately managed adventure activities which enhance individuals and our communities, while protecting the environment and culturally significant places. In doing this, these documents can help ensure that people will continue to enjoy the benefits of adventure activities well into the future.

Best wishes for all your adventures.

The Australian Adventure Activity Standard Steering Committee.

About these documents

The Australian Adventure Activity Standard (AAAS) and related Good Practice Guides (GPG’s) are a voluntary good-practice framework for safe and responsible planning and delivery of outdoor adventure activities with dependent participants.

The AAAS and related GPG’s provide guidance on safety and other aspects of responsible activity delivery, such as respect for the environment, cultural heritage and other users. They are not a full legal compliance guide, nor are they a “how to” guide or field manual for outdoor activities. They do not provide guidance on providing a high-quality experience over and above safe and responsible delivery.

Activity providers are encouraged to obtain independent professional and legal advice in relation to their obligations and duties in delivering adventure activities and should reference the relevant laws to the area in which they intend to undertake the adventure activity.

Does the Standard and Good Practice Guides apply to me?

The AAAS and related GPG’s are specifically designed to help activity providers who are conducting activities involving dependent participants, to provide a safe and responsible experience. It is for each provider to determine based on their own individual circumstances, if they are working with dependent participants or not.

A dependent participant is a person owed a duty of care by the activity provider who is reliant upon the activity leaders for supervision, guidance or instruction to support the person’s participation in an activity. For example, this often includes participants under the age of 18, participants lacking the ability to safely undertake the activity, or participants reasonably relying on the activity provider for their safety. The degree of dependence may vary during an activity.

Considerations for determining if a person is a dependent participant may include, but is not limited to:

- the foreseeable level of competence of the participant in the activity and the associated level of reliance this creates on the activity leaders

- the level of foreseeable self-reliance of the participant to reasonably manage their own safety

- the possible variation throughout the activity of the level of reliance

- the variation of the degree of dependence throughout the activity

- the individual context, nature and circumstances of the activity

- the relevant circumstances and particular facts relating to the responsibilities assumed by the provider.

An activity provider can be any organisation – business, community group, government agency, school or any other groups – that organises and leads adventure activities. Individuals can also be an activity provider, if they have the ultimate legal duty of care to participants. In general, ‘the Standard’ and GPG’s relate to a provider as a ‘whole organisation’, rather than to ‘specific roles’ within the provider ‘organisation’.

Some providers may have their own standards or guidelines appropriate to their duty of care. It is recommended that these be reviewed periodically to ensure current duty of care expectations are met. ‘The Standard’ and ‘GPG’s’ may aid such reviews.

Are they legally binding?

The AAAS and GPG’s are voluntary, not legal requirements. However, they may refer to specific laws and regulations which may be legally binding on activity providers.

While the AAAS and ‘GPG’s’ are voluntary, some land managers and other organisations may require compliance. This may be as a condition of obtaining a licence, permit or other permission, or some other condition (e.g. a contract).

Under Australian common law and relevant legislation, providers have a legal duty of care towards dependent participants in some circumstances. In broad terms, the legal duty requires providers to take reasonable care that their actions and omissions do not cause reasonably foreseeable injury to dependent participants.

The AAAS and GPG’s are not legal advice, and they cannot answer whether a legal duty exists in specific circumstances. All adventure activity providers should check what legal requirements apply in their own situation and seek legal advice if at all in doubt.

Even in cases where participants are not dependent, other legal duties and obligations may arise. The AAAS and GPG’s have not been developed for those contexts.

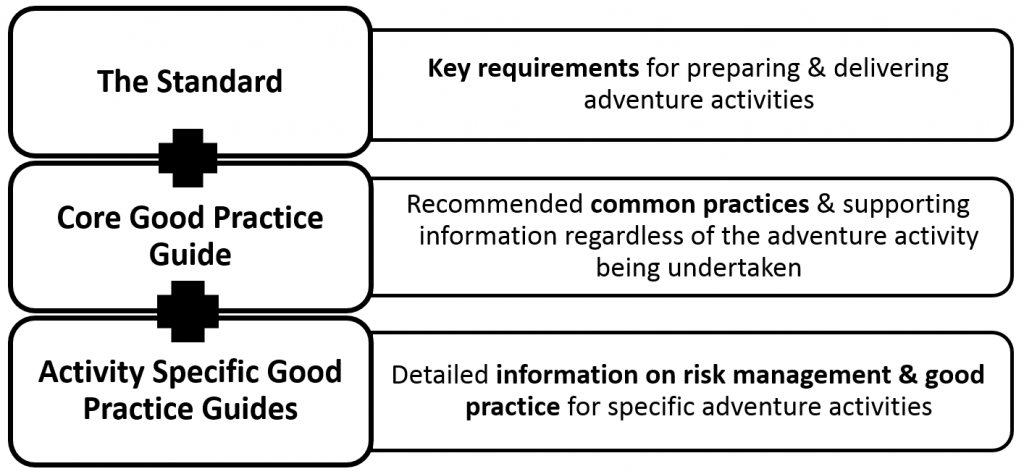

Structure of the Standard and Good Practice Guides

The AAAS (i.e. the Standard) has a related Core Good Practice Guide (Core GPG). They both include guidance that applies to all adventure activities. They set out recommendations for a common approach to risk management that can generally apply regardless of the specific activity being undertaken.

Individual activity Good Practice Guides include guidance on specific adventure activities.

For any given activity, (i) the AAAS (the Standard), (ii) the Core GPG and (iii) the activity Good Practice Guide that applies to that specific activity, should be consulted.

The AAAS and Core GPG cover only those activities specifically listed. While the AAAS and Core GPG may be useful in managing risk generally for other activities, they may not reflect good practice for such other activities.

Interpretation of the Standard and Good Practice Guides

The following words and phrases are used in all documents and have specific meanings:

- Must: used where a provision is mandatory, if the provider is to operate fully in accordance with AAAS or GPG’s. (This is equivalent to the keyword “shall” used in other voluntary standards e.g. Standards Australia, other International Standards Organisations (ISO’s) etc.)

- Should: used where a provision is recommended, not mandatory. It indicates that the provider needs to consider their specific situation and decide for themselves whether it applies or is relevant.

- Can/cannot: indicates a possibility and capability.

- May/need not: indicates a permission or existence of an option.

- But are/is not limited to: used to indicate that a list is not definitive and additional items may need to be considered depending on the context.

The following formatting is used throughout:

- Defined words are in italics. They are defined in the Glossary.

- Examples are in smaller italic 9-point font.

- In document references are in underlined. References are to section heading titles.

- External web or Australian AAS & GPG document links are in dotted underline italic.

Creation

The AAAS and GPG’s were developed with the input from a wide range of outdoors and adventure activity experts with extensive field experience. They draw on state and territory-specific standards previously in place across Australia. The development process included work by a range of technical expert working groups, as well as open consultation throughout the community of activity providers and other experts.

The Steering Committee wishes to thank all the Technical Working Group (TWG) members for their work and contributions.

The Steering Committee acknowledges all the State and Territory Governments for funding the creation of the first national adventure activity standard and set of good practice guides for the sector.

Further details of the creation of the AAAS and GPG’s can be found at australianaas.org.au/about/history/

It is intended that the AAAS and GPG’s will be regularly updated to reflect changing practice and better understanding over time. Updates will be noted on the website www.australianaas.org.

1 Introduction

1.1 Challenge courses

A Challenge Course is a temporary, mobile or permanent physical structure comprising of either an individual or series of elements, where a person requires a fall protection system should they fall from an element. A challenge course may include slacklining and activities at ‘play centers’ and ‘climbing adventure centers’. A challenge course excludes structures or elements that involve abseiling, rock climbing, artificial surfaces climbing or bouldering (refer to the Abseiling and Climbing GPG for these activities).

Challenge courses are also known as challenge ropes courses. Participants are required to use dexterity, strength, balance and complex physical movements to successfully traverse the element or course of elements. Challenge courses are often used for experiential learning, personal challenge or team building purposes but also for entertainment. Adventure games and low obstacles may also be a part of the challenge course.

Fall protection systems differ for low elements, adventure games and high elements.

Low element(s) (also known as low ropes or obstacle courses) is any element or series of elements for which the appropriate fall safety is achieved through spotting and/or an impact absorbing system. Some physical structures do not require fall safety and are called low obstacles to indicate when this is the case.

Spotting is a support process provided by a person, or persons, who offer physical protection of the head and upper body of a person should they fall.

High element(s) (also known as high ropes) is any element for which safety can no longer be achieved by spotting and requires a belay system using harnesses and specialist safety equipment or other established methods or systems. High elements may include but is not limited to swinging elements as well as flying foxes. In some circumstances spotting may be required while transitioning from a low to high fall height or visa-versa, as the ‘stretch’ in the belay system means it can only function as intended over a certain fall height.

An element is considered a temporary element when it remains in place no longer than seven consecutive days.

Adventure games (also known as initiative games) are activities which are not identifiable as a low element or high element activity, but which require spotting to ensure participant safety. Adventure games may be conducted as separate activities or as part of a warm-up for challenge course activities. Adventure games are covered by this GPG.

1.2 Exclusions

Activities that are not covered by this GPG are:

- abseiling either on natural or artificial surfaces (refer Abseiling and Climbing GPG)

- bouldering either on natural or artificial surfaces (refer Abseiling and Climbing GPG)

- games, sports or activities that are not Adventure Games

- rock climbing either on natural or artificial surfaces (refer Abseiling and Climbing GPG)

- activities that do not involve a belay system (e.g. mud runs, ‘playground equipment’, etc)

- competitive activities (e.g. adventure races, etc.).

1.3 Related activities

Possible related activities may include:

- abseiling, climbing or bouldering either on natural or artificial surfaces (refer Abseiling and Climbing GPG).

2 Management of risk

Refer to the Core Good Practice Guide – Management of risk.

2.1 Management of risk

There are no additional specific activity provisions other than Core GPG – Management of Risk provisions.

3 Planning

Also refer Core GPG – Activity Planning.

3.1 Activity plans

Additional challenge course activity planning considerations may include but are not limited to:

- site characteristics such as:

- supervision line of sight

- waiting areas

- element characteristics such as:

- difficulty

- height

- belay system used

- activity leader competencies required

- activity progression

- appropriate warm-up or lead-up activities (e.g. trust, cooperation, communication)

- suitable options to allow “challenge by choice”

- operating procedures and instructions that need to be provided

- participant training required (e.g. spotting, belaying, attaching to safety systems)

- any other relevant considerations listed in this document and the Core GPG.

3.2 Emergency management planning

Refer Core GPG – Emergency management planning.

The use of relevant rescue systems and procedures must be practiced periodically.

4 Participants

Refer Core GPG – Participants.

4.1 Information provided pre-activity

Pre-activity information should clearly communicate:

- expectations and activity conditions

- as per Core GPG – Participants.

An appropriate pre-activity assessment should be conducted to ensure participants have the necessary pre-requisite skills & knowledge to undertake the activity.

4.2 Participant considerations

Appropriate procedures must be in place to address risks associated with participants living with or experiencing an impairment.

Also refer Core GPG – Participants: Restrictions.

4.3 Participant health and wellbeing

Potential measures to assist in providing positive participant experiences may include but are not limited to:

- providing the activity as an option so it is ‘challenge by choice’

- providing a scaled level of experience to build participants level of skill, knowledge and experience

- providing real choice in terms of activity entry and exit options

- providing a briefing of hazards and risks and how these are managed

- considering the group dynamics when grouping participants

- providing emotional support through a supportive environment and positive rapport

- building and maintaining positive relationships within the group

- reducing as much as practical any discomfort from the equipment used.

5 Environment

5.1 Environment and site related planning

For course and element details refer to section 6.1 Artificial surfaces and elements design and construction.

Other environmental considerations other than climate or weather for challenge courses may include but is not limited to:

- the possible fauna at the challenge course

- the terrain surrounding the challenge course.

5.2 Course design and construction

Refer to section 6.1 Artificial surfaces and elements design and construction.

5.3 Weather

5.3.1 Weather information

Appropriate sources must be used for:

- current and forecast weather

- current and forecast weather warnings.

5.3.2 Weather warnings

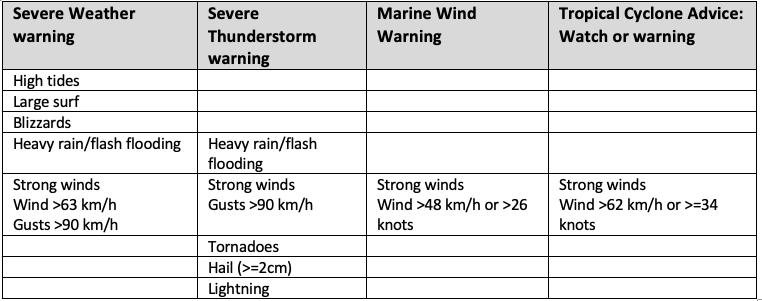

Refer Appendix 7 Weather warnings.

5.3.3 Weather triggers

Trigger points must be based on relevant Bureau of Meteorology weather forecasts and warnings and actual weather conditions.

The risk management plan and emergency management plan should include guidance on trigger points and associated actions for:

- wind speeds or wind gusts that make the course or element(s) unsuitable for use

- weather conditions that limit visual/verbal direct supervision

- lightning

- severe weather warnings

- thunderstorm warnings

- tropical cyclone advice: watch and warning

- cold temperature

- extreme hot temperatures.

Actions for weather triggers may include but are not limited to:

- cancellation of activity

- postponing the activity

- modifying the activity

- evacuating to a safe location

- avoid locations effected by tides or surf

- avoiding areas that have the potential for flash flooding

- preparations to avoid the risks associated with lightning

- preparations to avoid the risks associated with blizzards

- moving to areas that are protected from strong winds and/or hail

- managing risks of flying or falling items during strong winds.

5.3.4 Lightning

A lightning risk management procedure must be developed for the site.

Whilst thunder is audible groups should avoid:

- being on high elements

- being in unsuitable locations.

When thunder is audible, a suitable location should be sought, to wait out the thunderstorm.

Considerations for locations to waiting out the thunderstorm should include but not limited to avoiding:

- being on high elements

- being connected to metal structures, cable or equipment

- being on the highest ground in the area

- tall trees or structures that may act like a lightning rod

- water saturated ground near watercourses

- locations where a group is unable to spread out.

5.4 Bushfire, prescribed fire and fire danger

Refer Core GPG – Bush fire, prescribed fire and fire danger.

5.5 Flooding

Areas subject to flooding or flood warnings should be avoided.

Areas likely to experience flash flooding should be avoided during severe weather or thunderstorms.

5.6 Wildlife safety

Procedures should be in place to minimise the risks associated with any fauna or flora that may be encountered.

The types of wildlife encounters that may need to be considered include but is not limited to:

- snakes

- ants

- bees

- wasps

- nesting birds

- other local fauna.

5.7 Tree safety

Refer Equipment sections 6.1 Artificial surfaces and elements design and construction and 6.6 Inspection and maintenance regarding requirements relating to courses or element(s) using trees as part of their structure.

Weather based trigger(s) as to when to avoid operating activities in or below trees should be established.

Where element(s) are located or the activities are regularly conducted under trees, a risk assessment of the trees by an appropriately competent person must be completed periodically.

5.8 Environmental sustainability information

5.8.1 Design and construction environmental sustainability

For environmental sustainability considerations refer to AS 2316.2.1:2016 Artificial climbing structures and challenge courses Part 2.1: Flying foxes and challenge ropes courses—Construction and safety requirements (EN 15567-1:2007, MOD). This may include items relating to flora and fauna (e.g. tree usage, root systems, native habitats, etc.).

5.8.2 Temporary elements environmental sustainability

As per section 5.8.1 above.

5.9 Environmental sustainability procedures

The procedures may include but is not limited to procedures listed in Core GPG – Environmental sustainability and the following:

5.9.1 Travel and camp on durable surfaces

Travelling in an area on durable surfaces may include but is not limited to:

- utilise recognised tracks to approach and move within the challenge course

- locate waiting areas that have a firm base and can tolerate groups without causing vegetation damage and erosion

- actively managing participants to minimise trampling and damage to the surrounding vegetation

- utilise temporary erosion control or vegetation protection measures in heavy traffic areas around elements.

5.9.2 Leave what you find

Leave what you find may include but is not limited to:

- rope protectors or slings should be used to protect trees or other vegetation if used for belay points

- steps should be taken to prevent soil compaction around the roots system of living trees.

5.9.3 Be considerate of your hosts and other visitors

Be considerate of your hosts and other visitors may include but is not limited to:

- locate equipment, active participant(s) and participants non-actively participating so they allow free access to tracks

- encourage quiet communication to minimise the noise.

6 Equipment and logistics

6.1 Artificial surfaces and elements design and construction

Construction and/or operation of challenge courses must conform with any legislative or regulatory requirements of the relevant jurisdiction the activity operates in. (For example, ‘amusement’ structure laws.)

Permanent artificial surfaces and element(s) constructed specifically for use in activities must comply with relevant construction standards.

The relevant standard may include:

- AS 2316.2.1:2016 Artificial climbing structures and challenge courses Part 2.1: Flying foxes and challenge ropes courses—Construction and safety requirements (EN 15567-1:2007, MOD)

- AS 3533.1-2009: Design and construction

- AS 3533.1-2009/Amdt 1-2011: Design and construction

- AS 3533.2-2009: Operation and maintenance

- AS 3533.2-2009/Amdt 1-2011: Operation and maintenance

- AS 3533.3-2003: In-service inspections

- AS/NZS 4422:1996 Playground surfacing— Specifications, requirements and test method

- EN 795: Personal fall protection equipment – anchor devices.

Permanent artificial surfaces and element(s) constructed using superseded construction standards should be reassessed for ongoing suitability for use during maintenance inspection.

Temporary artificial surfaces and/or temporary element(s) should comply with either permanent artificial surfaces relevant requirements or be assessed by a competent person that it is fit for purpose for the activity.

Design of high element(s) and challenge courses must allow the use of an appropriate rescue system.

Systems must have a functional inspection to confirm it is appropriately constructed and operates or performs its required function. Refer Appendix 5 Inspections and maintenance additional detail.

6.2 Equipment general

6.2.1 Equipment general principles

All equipment must be used with reference to the manufacturers instructions.

Training in the use of equipment used must be provided to activity leaders and participants.

Before use, the compatibility between and the correct functioning of all equipment must be confirmed.

The elements used must be of a height that the fall height will allow the fall safety system to operate effectively.

Operation of challenge courses must conform with any legislative or regulatory requirements. (For example, ‘amusement’ structure laws.)

Equipment, connection methods and systems used must be periodically reviewed.

Equipment used must be

appropriate for the activity context.

Equipment listed below must be manufactured for use in the context of the activity:

- accessory cord

- artificial fixed anchors used in elements

- ascending devices

- belay devices

- cables, wires and other fixed ropes

- carabiners or other connectors

- descending devices

- dynamic rope

- harnesses

- helmets

- lanyards

- pulleys

- slings

- static rope

- any other equipment relied upon for safety systems.

6.2.2 Equipment loading

Equipment designed to be under load will have a stated strength that may or may not include a safety factor. The type of stated strength rating needs to be known before use to ensure equipment is safely loaded. (Refer Appendix 3 Equipment load ratings for more details).

Equipment with the stated strength providing the Minimum Breaking Strength (MBS) must have a suitable safety factor applied and a Safe Working Load (SWL) calculated.

Equipment with the stated strength providing the Safe Working Load (SWL) must be loaded only to a maximum of the Safe Working Load (SWL).

Reference to the manufacturers instructions must occur when determining a safety factor and/or safe working load.

The expected peak load and possible additional loads if a rescue is carried out must be considered when determining equipment loading.

6.2.3 Smoking

There must be no smoking near and/or while wearing safety equipment.

6.3 Fall safety management systems

6.3.1 Fall safety systems

All safety equipment used in the safety management system and/or a belay system must be appropriate for the task.

An appropriate safety system must be used when at height on all high elements.

Procedures used for belay systems must be suitable for the equipment.

Procedures and systems used should be consistent throughout the challenge course activity session.

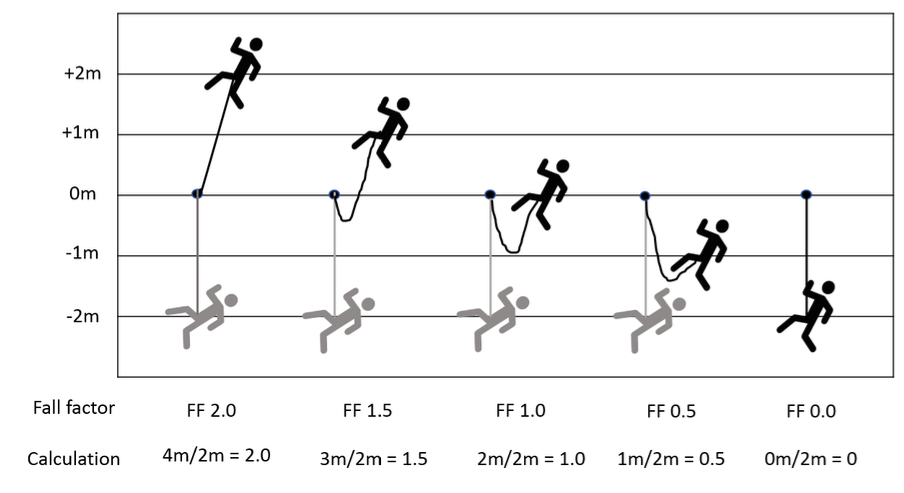

Any belay system or lanyard must be appropriate for the expected fall factor of a climber.

Also refer section 7.5 Fall safety systems management.

6.3.2 Ropes and lanyards used

The type of rope used in a belay system must be appropriate for the type of high element.

Considerations for selecting when dynamic rope or static rope is suitable for a belay system should include but is not limited to:

- the expected fall distance before the belay system halts the fall

- the amount of impact loading expected on the climber

- the fall factor involved

- if the elasticity of a dynamic rope during a fall may increase the risk of injury

- the amount of slack rope likely to be in the belay system, which may increase the fall distance and therefore the impact loading and fall factor on the climber.

Safety lanyards must be made of a suitable material (e.g. flat webbing, tubular webbing, static or dynamic rope of suitable diameters) that has an appropriate safe working load.

6.3.3 Connections

The connection system used must always provide an appropriate safe attachment, including at changeover/transition points.

Connection methods, equipment and systems used must be periodically reviewed.

Considerations when determining connection methods, equipment and systems must include:

- the type of equipment being used

- what systems if any are required to provide redundancy

- what needs to be attached and how

- the experience and context of who is completing the connection

- the availability of a competent person to supervise or check the connection that is completed by a participant.

6.3.4 Connectors – practices relating to use

The type of connector used must be suitable for the task.

Considerations for determining the type of connector suitable for a task must include:

- the likelihood of misalignment and/or loading the gate

- the likelihood of it becoming unlocked and/or disconnecting via a rollout

- the way it will be loaded

- the amount of exposure to vibration

- how often inspection of the connection can occur

- material the connector is made of compared to the type materials it will connect to.

Connectors made from appropriate materials must be used when connected to metal wire.

Carabiners must be used so that no load is across the minor axis or gate.

Systems that have loads applied and released so that alignment of connectors or equipment may change, or subject to vibration should be inspected at an appropriate frequency.

6.3.4.1 Harness connections

The connection of the harness must use:

- an appropriate knot to tie in or

- two methods of connection to provide redundancy, with any carabiners used being locking carabiners or

- a ‘three way’ auto-locking carabiner where ‘clipping in’ is the soles means of attachment or

- an appropriately tied girth hitch or

- a tool locked connector.

If using a locking connector (e.g. screwgate carabiner) to connect to a climbers harness, the connection must use two locking connectors in opposed orientation to each other.

The connection of the belayers harness to a belay device must use either a locking carabiner or auto-locking carabiner.

In situations where participants complete any connection to a harness:

- the connector or knot must be checked by a competent person

- and when a competent person may not check the connection, two methods of connection to provide redundancy must be used.

6.3.4.2 Lanyards connections to anchors and critical lines

The connection attaching climbers lanyards to any anchor points or critical lines must use:

- an auto-locking carabiner or

- an interlocking device or

- a tool locked connector.

6.3.5 Harnesses

Where required an appropriate harness must be used on all high elements.

6.3.5.1 Full body harnesses and combination chest & sit harnesses

Chest harnesses must only be used in combination with a sit harness.

A full body harness or combination chest and sit harness eliminate several potential harness related risks for challenge courses and it is suggested that when updating equipment, a preference for using full body harness’s is considered.

The risk assessment should assess if harnesses need to be a full body harness or a combination chest and sit harness.

Use of a full body harness or combination chest and sit harness should be considered:

- for flying foxes and giant swings

- when inversion is intended or likely

- when the security of a sit harness cannot be relied upon due to body shape of the person

- when the security of a sit harness cannot be relied upon if the person were to experience a pre-existing health, medical or personal condition episode (e.g. epilepsy)

- for the very young

- based on the expected length of time in harness and positioning (e.g. extended time periods at height)

- based on law or regulatory requirements

- whenever updating harness equipment, given they eliminate several potential risks listed.

6.3.6 Rescue equipment

Appropriate vertical rescue equipment must be readily accessible.

Rescue systems used should be rated to carry a minimum of two people.

Rescue systems used should be able to be used to lift and to lower.

Considerations for rescue systems should include but is not limited to:

- load direction including multi-direction loads

- load magnitude

- ability to raise the person and rescuer

- ability to lower the person and rescuer

- ability to enable an activity leader to complete contact rescues.

Vertical rescue equipment may include but is not limited to:

- ascending device(s)

- belay device(s)

- carabiners (alloy/steel)

- claws or cowstails

- knife (preferably a rescue hook knife)

- lanyards

- pulleys

- prusik loops

- pair of pliers or multi-grips

- rescue rope equivalent in length to greater than twice the height of the highest element or belay wire or anchor point should be accessible and available for rescue

- slings

- relevant tools for opening devices or connectors.

Example equipment lists can be found in Appendix 1 Challenge course equipment.

6.3.7 Assisted belay

Refer to sections above: 6.3.1 Fall safety systems, 6.3.2 Ropes and lanyards used, 6.3.4 Connectors – Practices relating to use, 6.3.5 Harnesses and 6.3.6 Rescue equipment.

6.3.8 Self-belay including continuous self-belay

Also refer to sections above: 6.3.1 Fall safety systems, 6.3.2 Ropes and lanyards used, 6.3.4 Connectors – Practices relating to use, 6.3.5 Harnesses and 6.3.6 Rescue equipment.

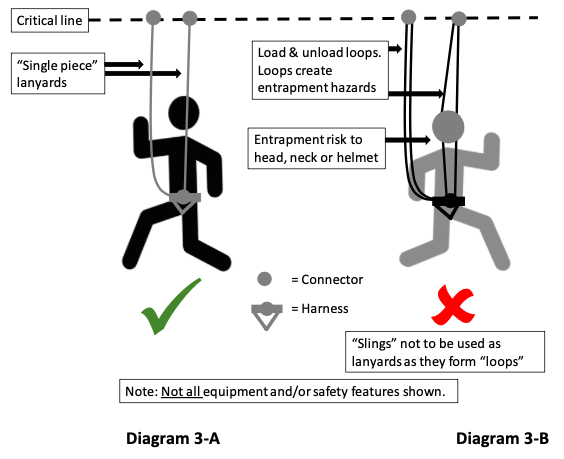

6.3.8.1 Self-belay system lanyards – Single piece or sheathed

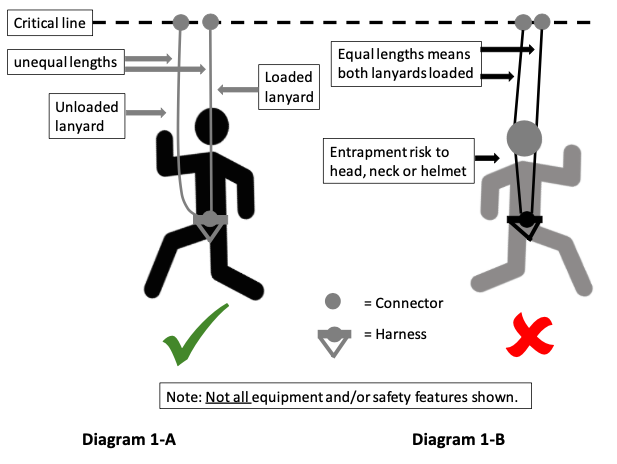

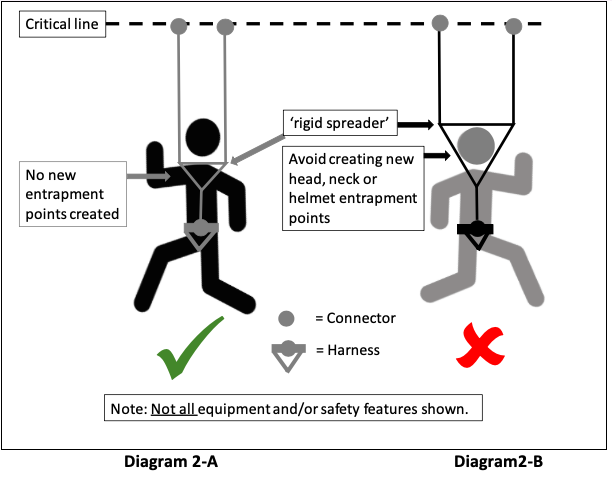

Self-belay systems with lanyards must be designed to minimise possible user entrapment and pressure on the neck, head and/or helmet that may cause strangulation when loaded. (Refer Appendix A6.3 Single piece or sheathed lanyards.)

6.3.8.2 Self-belay system with two safety lanyards

Self-belay systems with two safety lanyards must be designed to minimise possible user entrapment and pressure on the neck, head and/or helmet that may cause strangulation when loaded. Refer Appendix 6 Safety diagrams for lanyards.)

While progressing across an element while using a two-safety lanyard system, both lanyards of the self-belay system should be attached to the critical line.

6.3.9 Collective safety systems

Collective belay systems must have a functional inspection to confirm it is appropriately constructed and operates or performs it’s required function.

6.3.9.1 Soft-fall

Soft-fall used to protect from falls from height must conform to AS 2316.1—2009 – Part 1—2009 Artificial climbing structures and challenge courses Part 1: Fixed and mobile artificial climbing and abseiling walls.

Where soft-fall is relied upon without the use of spotting it must cover the whole of the expected fall zone.

6.3.9.2 Barriers

Any barriers, railings or banisters to protect from a fall from height must conform to relevant building codes.

6.3.9.3 Deep Water

Any deep water pools used to protect from falls of height must conform with any required ‘pool safety’ legislative or regulatory requirements of the relevant jurisdiction the activity operates in.

Deep water to protect from falls of height must cover the whole of the fall zone.

The depth of water used to protect from falls of height must be sufficient so a person who falls unprepared avoids hitting the bottom. (For example, deep enough if they fall and ‘pin drop’.)

The fall height into deep water used to protect from falls of height must be limited to protect a person falling from injury.

The deep water pool must allow suitable entry and exit from the water.

The deep water pool must have any required infrastructure to manage access (e.g. fencing and gates to prevent accidental child drownings etc.)

The water within the deep water pool must be suitable for a person to swim in.

6.3.9.4 Safety netting

Nets used to protect from falls from height must conform to:

6.3.10 Participant supplied safety equipment

Where a participant supplies any personal safety equipment, this must comply with this GPG and be appropriate and serviceable.

A procedure regarding participant supplied safety equipment should be developed.

6.4 Other equipment

6.4.1 Helmets

A risk assessment must determine when active participant(s) are required to wear a helmet.

A risk assessment must determine if anyone non-actively participating is required to wear a helmet.

Considerations for wearing a helmet must include risks of:

- head injury from falling objects

- strangulation by the helmet chin strap caused by a helmet entrapment

- head injury from striking the head during falls or swings.

When a helmet is required to be worn it must be an appropriate helmet for the situation.

Areas and activities that require a helmet to be worn must be identified.

A helmet should be worn while climbing on high elements.

A helmet should be considered when climbing on low elements.

Also refer to 7.4.9 Falling objects, 7.4.10 Entanglements and snags, 7.5.3.1 Two lanyard safety systems and Appendix 6 Safety diagrams for lanyards.

6.4.2 Clothing

Procedures must be in place to ensure appropriate clothing is worn.

Considerations when determining appropriate clothing should include but is not limited to:

- the requirements of the element(s) being used

- sun protection

- the weather conditions.

Also refer to 7.4.10 Entanglements and snags.

Footwear must be fit for purpose.

Procedures must be in place to ensure appropriate footwear for the expected and foreseeable terrain is used.

6.4.3 Other personal equipment

Procedures must be in place to ensure a suitable drinking water supply is available.

6.5 Pre-activity equipment preparation and inspection

All equipment must be checked that it is serviceable before each activity or before being used.

Consideration should be given to implementing checks for damage in situations where unsupervised community access to equipment or elements could occur (e.g. public access sites, vandalism, etc).

A daily operations sheet should be used to record equipment and setup checks. (Refer to Australian Standard AS 2316.2.2)

6.6 Inspection and maintenance

Maintenance inspections must conform with any legislative or regulatory requirements.

Compliance with the Australian Standard AS 2316.2.1:2016 may include but is not limited to inspection, testing and maintenance requirements.

All elements and anchors used must be periodically inspected by an appropriately competent person, as per any relevant construction standard (see appendix 2 for examples), designer and/or constructor recommendation(s).

Appropriate procedures must be in place for inspections and determining the time periods between inspections.

Considerations for how regular the inspections occur may include but is not limited to:

- the characteristics of the site

- how many people use the site and how regularly

- any manufacturers, designers or constructors recommendations where relevant

- the equipment being used.

Any tree used as part of an element should be periodically inspected by an appropriately competent person such as an arborist.

Any tree located within the challenge course area that presents a falling object risk should be periodically inspected by an appropriately competent person (e.g. arborist).

All equipment must be inspected periodically that it is serviceable.

Inspections should include but is not limited to:

- surrounding area and ground

- physical structures

- materials and fittings

- safety equipment.

Equipment and inspection records must conform with any legislative or regulatory requirements.

A record of inspection must be maintained.

Refer Appendix 5 Inspections and maintenance for additional detail.

An equipment record should be maintained.

Where used an equipment record should record but is not limited to the:

- item individual identifier

- date of purchase

- date of inspections

- recommended or maximum lifespan.

A retirement of equipment policy should be developed.

Considerations for a retirement of equipment policy may include but is not limited to:

- type of use

- frequency of use

- prevailing conditions when used

- actual deterioration, wear and tear

- age

- years in service

- manufacturers recommendations.

A system to identify equipment and elements should be used to assist reporting and recording faults or condition checks.

6.7 Storage of equipment

Activity equipment must be stored in accordance with the manufacturers recommendations or instructions.

Where no manufacturers recommendations exist, considerations for storage of equipment may include but is not limited to:

- equipment is clean and dry

- the storage is free from harmful chemicals

- the storage is free from damp conditions

- the storage is free from environmental exposure including Ultra Violet (UV) light and avoids extremes of temperature

- the equipment is free from interference from animals/pests.

7 Leadership

7.1 Leadership terminology conventions used

7.1.1 Level of supervision terms

A system to describe the different level of supervision must be used. (See an example system below.)

Supervision used can be described by the “level of supervision”. This document uses the following three levels of supervision:

- Level 1 – where a nominated person responsible for supervising others during all or part of the activity is able to physically intervene immediately. (Aligns with level 1 in AS 2316.2.2:2016 and direct supervision in the Core GPG).

- Level 2 – where a nominated person responsible for supervising others during all or part of the activity is able to visually see the participant(s) and verbally intervene immediately. (Aligns with level 2 as per AS 2316.2.2:2016 and direct supervision in the Core GPG).

- Level 3 – where a nominated person responsible for supervising others during all or part of the activity is in the vicinity and able to respond promptly to provide assistance when called upon. (Aligns with level 3 as per AS 2316.2.2:2016 and indirect supervision in the Core GPG).

7.1.2 Leader naming conventions

The activity leader naming convention enables activity leader requirements in this activity Good Practice Guide to be related to Core GPG requirements.

The leadership naming conventions for challenge course activities are:

- Manager and Supervisor is equivalent to Leader in Core GPG.

- Instructor is equivalent to Assistant leader in Core GPG.

- Activity leader is a collective noun referring to instructor(s), supervisor(s) and/or manager(s).

7.1.2.1 Instructor

Instructor (also known as a conductor): A person with the competence to supervise participants who are active participants on challenge course element(s). An instructor may be a challenge course instructor: low elements and/or an instructor: high elements.

The competence of an instructor generally means that they:

- require defined operating procedures to follow when supervising participants

- require Level 3 supervision by a supervisor or manager so that assistance is readily available if a non-routine situation arises

- guide participants but there is no intention of imparting activity skills or knowledge to participants beyond that which is necessary to enable their safe participation, although the conduct of the activity may achieve other education outcomes.

7.1.2.2 Supervisor

Supervisor: A person with the competence to independently supervise participants who are active participants on challenge course element(s). A supervisor may be a challenge course supervisor: low elements and/or a supervisor: high elements.

The competence of a supervisor generally means that they:

- do not require supervision when supervising participants use of element(s)

- can apply their skills and knowledge to a broad variety of challenge courses and elements

- can provide Level 1, 2 or 3 supervision of instructor(s)

- are be able to deal with non-routine situations

- are able to teach the skills and knowledge required to conduct activities (i.e. able to train instructors).

7.1.2.3 Manager

Manager: A person with the competence to be a supervisor and to manage and maintain a challenge course. A manager may be a challenge course manager: low elements and/or a manager: high elements.

The competence of a manager generally means that they:

- can undertake all necessary activities related to a challenge course including supervisor roles

- can provide Level 1, 2 or 3 supervision to instructors and supervisors

- undertake or manage the maintenance of the course or elements.

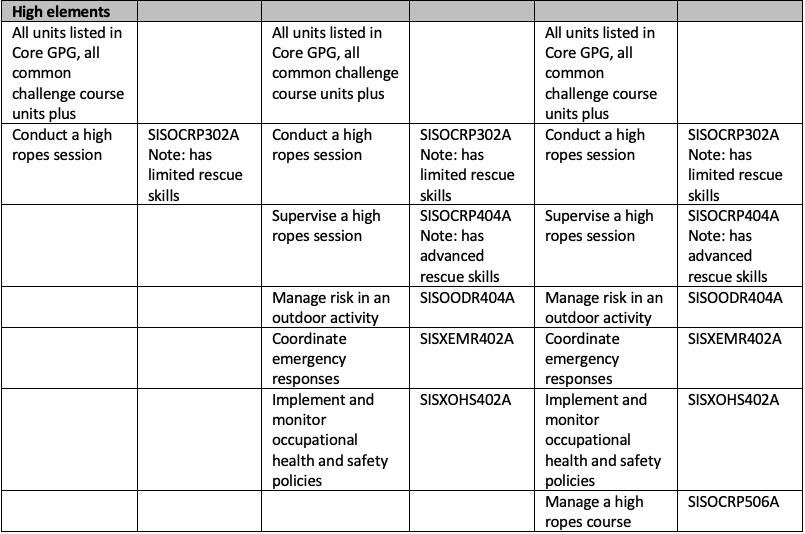

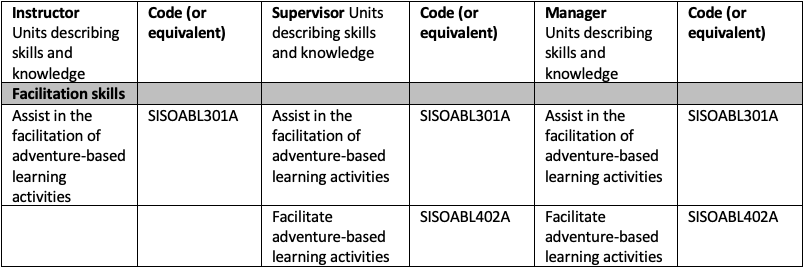

7.2 Competencies

7.2.1 Competencies overview

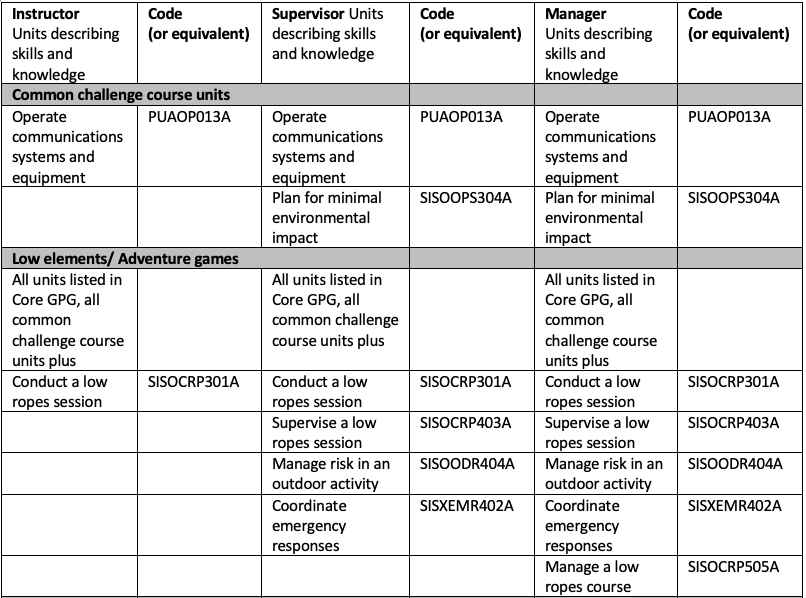

The Australian Adventure Activity Standard and Good Practice Guides refers to units from the Sport, Fitness and Recreation Training Package for descriptive statements of the knowledge and skills required of activity leaders.

The Training Package units are used for the sole purpose of providing descriptions for the knowledge and skills required. It is not intended to imply or require that specific formal training, assessment or qualification is the only means of gaining or recognising knowledge and skills.

Providers can recognise activity leaders as having the ‘ability to apply knowledge and skills to achieve expected results’ (i.e. competencies) in a number of different ways as detailed in Core GPG – Recognition of competence.

The Training Package units listed can be found by searching for the units on the training.gov.au/Home/Tga website. The code provided with the unit name assists in this search.

7.2.2 Challenge course competencies

Also refer to Core GPG – Competencies.

Refer to Appendix 9 Activity leader competencies.

7.2.3 Recognition of competence pathways

Refer to considerations for recognition pathways outlined in Core GPG – Competencies.

7.3 Supervision requirements

Also refer to the Core Good Practice Guide – Recognition of competencies.

7.3.1 Supervision plan

Supervision requirements must be documented in a challenge course supervision plan.

Activity supervision must be implemented according to the challenge course supervision plan.

A challenge course supervision plan must include:

- a course diagram for visual reference

- a summary of the risks identified in the risk assessment

- supervision requirements for the challenge course

- specific locations to operate supervision from

- obstructions (e.g. trees, structures, etc.) and/or conditions (e.g. sun location, mist, etc.) that may impact supervision visibility and procedures to overcome these

- relevant manufacturers specifications or requirements

- activity leader roles and responsibilities

- activity leader competencies including any special competencies for each element

- activity leader pre-deployment confirmation of competence, training or orientation required

- communications plan

- emergency response plan.

Also refer Appendix 8 Challenge course supervision plan.

7.3.2 Group size considerations

Considerations when determining group size must include:

- site capacity

- site related legislation or regulation

- the time allowed to enable all participants in the group to complete the activity is sufficient and realistic and does not compromise safety

- having appropriate supervision for participants non-actively participating

- considerations for determining group size outlined in Core GPG.

7.3.3 Supervision ratio considerations

Considerations in determining challenge course supervision requirements should include but are not limited to:

- the nature and design of the elements

- requirements for the belay system(s) and transfer between belay system(s)

- time for the activity leaders to allow all participants to undertake the activity being sufficient and realistic and does not compromise safety

- the ability to see and/or hear active participants

- the number of active participants enables activity leaders to adequately monitor, detect and correct improper procedures

- having appropriate supervision for participants non-actively participating

- the potential for activity leader fatigue

- emergency event and/or rescue requirements

- considerations for determining supervision requirements in Core GPG.

An appropriately competent person must establish supervision requirements and standard operating procedures for element(s) and/or the challenge course.

7.3.4 Participants that are non-actively participating

Consideration must be given to the type of supervision participants required when non-actively participating i.e. who are waiting to undertake the activity.

In cases where participants who are non-actively participating require Level 1 or 2 supervision, that supervision must be provided by an activity leader not providing Level 1 or 2 supervision of an activity or by a responsible person as appropriate.

7.3.5 Assessment of participants use of safety systems

Each participant must be assessed to confirm they have sufficient reach to use and operate the safety systems while retaining an appropriate footing. (For example, there may be a minimum height requirement to reach or connect belay systems.)

An assessment must be completed to confirm each participant is competent to carry out the relevant safety instructions and safety system operation.

The assessment to confirm each participant is competent to carry out the relevant safety instructions and safety system operation must be completed without exposure to risks, serious injury or death. (For example, use of test system or element.)

Where the participant

has been assessed as competent to carry out

the relevant safety instructions and safety system operation, ongoing

supervision must monitor and check the participants actual use for continued competence before adjusting the level of supervision.

7.3.6 Supervision provided

Supervision for collective belay systems must be determined by the risk assessment and supervision plan.

The maximum number of separate elements one activity leader can supervise must be determined by the risk assessment and supervision plan.

7.3.6.1 High elements supervision

When high elements are in use there must be at least one activity leader available with supervisor or manager competencies.

All people at height irrespective of the level competence must be appropriately supervised.

When multiple active participants are at height on high element(s), there should be a minimum of two activity leaders included in the supervision plan.

7.3.7 Pre-activity course preparation supervision

A safety system must be used when undertaking pre-activity setup or safety inspection that has a fall from height hazard.

When a belay system is used, there must be another person:

- aware that the belay system is in use

- monitoring the setup of the activity or the safety inspection (e.g. level 3 supervision)

- who can promptly respond if there is an emergency.

7.3.8 Supervision of connectors & connections

Self-closing connectors that are non-locking must not be used.

All locking connectors that are not tool locked or auto-locking (e.g. screwgate carabiners) must be appropriately supervised throughout the activity to ensure they remain locked.

The first/initial connection of climbers and belayers to the safety system must be supervised or checked before being relied upon. (Refer 7.3.5 Assessment of participants use of safety systems above.)

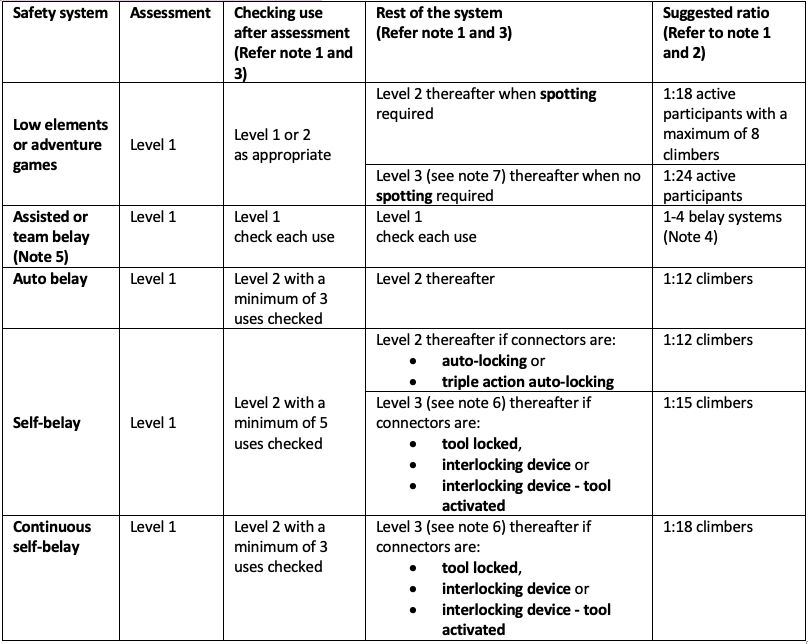

7.3.9 Supervision for different situations

The recommended level of supervision, minimum recommended usage checks and suggested supervision ratios that should be used are in the following table.

The table is to be used in conjunction with other 7.3 Supervision requirements sections above.

(Refer table next page.)

Supervision for different situations table

Notes:

- Use course designers or course builders recommendations for the site and/or elements when available. Site specific recommendations must be used in preference to generic suggestions that lack an understanding of the specific site or element involved.

- When site specific course designers or course builders ratio recommendations are not available, the suggested ratios in the table need to be revised for the specific site or elements by considering:

- 7.3.6 Supervision provided requirements and recommendations above and

- 7.3.2 Group size considerations section above and

- 7.3.3 Supervision ratio considerations section above.

- When site specific course designers or course builders levels of supervision and assessment checking recommendations are not available, the suggested assessment checking recommendations in the table need to be revised for the specific site or elements.

- An important consideration in determining the supervision ratio includes but is not limited to the proximity of the belay stations.

- Includes all other types of safety systems not specified elsewhere (e.g. haul systems, “donkey belays”, “glider possum” etc.)

- Use of Level 3 supervision on high elements must only be used where the course has a suitable design and equipment and appropriate procedures for participant induction, assessment and progress monitoring.

- Use of Level 3 supervision for low elements or adventure games when no spotting required must only be used where the course or adventure game is of appropriate design for the participants.

- Refer glossary for definitions for levels 1, 2 or 3.

7.4 Activity management

7.4.1 Knowledge of site

Activity leaders must have an induction to the activity site that includes supervision requirements in the supervision plan and any relevant specific activity site procedures.

The knowledge of the activity site that activity leaders require before leading participants at that site, should be considered when allocating activity leader roles.

7.4.2 Pre-activity equipment preparation

Rescue equipment must be checked that it is serviceable and ready for immediate use before each activity.

7.4.3 Activity leader positioning

Procedures should enable activity leaders to respond to emergencies and complete rescues in an appropriate time frame.

7.4.4 Activity leader fatigue and repetition

Considerations for activity leader fatigue should include but is not limited to:

- time required to complete tasks

- task repetition

- weather (e.g. hot temperatures etc.).

Considerations in managing activity leader fatigue and task repetition risks should include but are not limited to:

- group sizes and the number of groups

- role rotation

- suitable breaks.

7.4.5 Spectators

Any spectators should be directed to an appropriate waiting area to view the activity.

7.4.6 Participants belaying and spotting

Considerations for when participants operate belay systems must include:

- participants are willing and capable

- appropriate training is provided

- the need for ongoing monitoring to ensure:

- correct technique is used

- attention to the task is maintained

- equipment is used correctly

- backup systems to support the belayer (e.g. using a backup belayer)

- the relative weights between the belayer and climber, where the belayers weight is integral to the correct function of the belay and the belayer is not anchored.

Considerations for when participants are spotting should include but are not limited to:

- participants are willing and capable

- appropriate training is provided

- the need for ongoing monitoring to ensure:

- correct technique is used

- attention to the task is maintained.

7.4.7 Activity information for participants

The information required to be provided to participants must be determined prior to the activity.

Required information must be provided at the appropriate time before or during the activity.

Activity information that should be provided to low element or adventure game participants includes but is not limited to:

- appropriate personal clothing requirements

- relevant hazards and risks

- any expectations required of the participant

- specific areas they need to know about (e.g. waiting areas, belay areas, where safety equipment is to be worn, areas not to be entered)

- how to access the elements

- communications and systems used to manage the flow and safety of the activity

- the correct fitting of and care of any personal safety equipment

- appropriate technique(s) for the activity

- method for “falling off” and “recovering”

- correct method of spotting.

Activity information that should be provided to high element participants includes but is not limited to:

- information provided for low element or adventure game participants above

- element specific hazards or risks

- the correct use of the belay systems and/or any other fall protection systems

- appropriate technique(s) for the activity

- the release procedures for belay system or other system

- procedures for exiting or being lowered back down.

Where there is only has one activity leader, the group must be briefed on what action to take to enact the emergency management plan if the activity leader becomes injured or incapacitated.

7.4.8 Activity Communications

A clear & unambiguous communication system must be used to manage the activity.

For example:

- system of safety operation such as confirming “on belay” or “off belay”

- safety communication from activity leader to participant and activity leader to activity leader.

- safety communication participant to participant

- emergency situations.

7.4.9 Falling objects

Procedures to minimise the possibility or impact of falling objects must include:

- checking the site prior to use

- ensuring helmets are worn where relevant as per the equipment section

- designating waiting areas that reduce the expose to falling objects

- briefing participants on potential hazards and how to avoid dislodging objects

- briefing participants on the appropriate action and warnings to give if an object does fall

- managing groups so that the groups and individuals exposure within potential falling object areas is minimised

- minimising movement between areas that are located below others

- supervision of participants while they are located above others.

Procedures to minimise the possibility or impact of falling objects should include but are not limited to:

- placing belay areas wherever possible so that they are not directly under the climber

- managing spectators and/or other people moving through the area.

7.4.10 Entanglement and snags

To avoid entanglement in ropes and devices:

- long hair must be secured to stop it being able to be entangled

- loose jewellery (e.g. bracelets and necklaces) and watches should be removed or secured

- loose clothing should be secured

- clothing and hat drawstrings should be secured.

To avoid being caught or snagged, where there is such a risk:

- rings should be removed or tapped over

- body piercings should be removed or taped over

- loose jewellery (e.g. bracelets and necklaces) and watches should be removed or secured.

The activity leaders should monitor belay rope(s) to keep them at the appropriate length and tension, to prevent the possibility of a slack rope becoming entangled or snagged.

7.4.11 Falls from height

Considerations for the likelihood of a fall from height should include but are not limited to:

- the stability and grip of the surface being stood on

- obstacles that need to be negotiated

- abilities of participants including the ability to follow instructions.

To protect from a fall from height, procedures must include checking participant(s):

- equipment is correctly fitted before they need to rely on the belay system

- correct attachment to the belay system, safety or other systems.

Checking equipment and attachment must not be delegated to the participants themselves, unless they have demonstrated competence in the procedure(s) and then only for checking their own equipment or attachment.

To reduce the potential for falls from height, procedures must include:

- ensuring ropes are of a sufficient length for the element

- removing unnecessary slack in belay system before use

- monitoring the correct use of belay systems

- monitoring attaching to anchors or belay systems

- monitoring belay rope(s) to keep them at the appropriate length

- monitoring belay systems to remove unnecessary slack in belay ropes

- providing appropriate instruction to mitigate risks caused by the stretch in dynamic rope.

To reduce the potential for falls from height, procedures should include:

- designating what areas that are not to be entered

- designating waiting areas

- designating areas that can only be accessed when attached to the belay system

- checking participants equipment is correctly fitted before they need to rely on the belay system

- checking correct attachment to the belay system, safety or other systems

- anchoring the belayer where the belay system relies substantially on the belayers weight to arrest a fall and the weight of the abseiler or climber is greater than that of the belayer.

Consideration must be given to the need for separately spotting climbers when starting their ascent, until such time the climber reaches a fall height where the belay system will full operate to stop their fall before they touch the fall zone.

7.5 Fall safety systems management

7.5.1 Belay and activity systems

Procedures to ensure that all activity leader supervised systems function as intended must include:

- anchor systems and equipment are suitable for the activity, site and participants

- appropriate knots and connections are used

- regular inspection of all anchors and connections where practicable

- operating procedures and checks used will prevent unplanned disconnection of any part of the system

- checking attachment and disconnection to the system during the activity.

Appropriate assessment should consider and address the possible differences between participant and activity leader usage of systems.

Where a belay system relies on a lanyard, throughout the climb the climbers harness attachment point should not be higher than the anchor point that the lanyard is attached to. (This means the fall factor on a lanyard should not exceed 1.0 – refer Appendix 4 Fall factors.)

7.5.2 Assisted belay

Where participants are belaying, they must be instructed and appropriately supervised.

Where a belay system requires a belayer, either the belayer must be:

- verified as a competent belayer or

- under Level 1 or 2 supervision of an activity leader.

7.5.3 Self belays

7.5.3.1 Two lanyard safety systems

Procedures must be in place to minimise the likelihood of placing a head/neck between the two lanyards when using a two-lanyard safety system. (For example, informing of procedures to reduce risk, lanyards are kept in front while using, lanyards are held together while progressing.)

7.5.3.2 Auto belays and continuous self-belays

Procedures to ensure that all auto belay and interlocking continuous self-belay systems function as intended must include:

- anchor systems and equipment are suitable for the activity, site and participants

- appropriate knots and connections are used

- operating procedures and checks used will prevent unplanned disconnection of any part of the system

- appropriate training of participants in use of the “automated systems”

- confirming competence of participants in using the “automated systems” prior to them undertaking the activity without Level 1 or 2 supervision

- ongoing level 3 supervision of the activity.

7.5.4 Collective belays

7.5.4.1 Barriers

A risk assessment and supervision plan must consider if monitoring is required to ensure fixed barriers are effective.

7.5.4.2 Soft-fall

A risk assessment and supervision plan must be used to determine the supervision required when falls from height are solely protected by soft-fall.

7.5.4.3 Deep water

Supervision of deep water pools used to protect from falls of height must conform with any required ‘pool safety’ legislative or regulatory requirements of the relevant jurisdiction the activity operates in.

Supervision arrangements must include:

- appropriate rescue requirements

- appropriate training of activity leaders responsible for water rescue

- Level 1 or 2 supervision visual supervision at all times in the event a person becomes unconscious while in the water.

7.5.4.4 Netting

A risk assessment and supervision plan must be used to determine the supervision required when falls from height are protected by netting.

7.5.5 Spotting belays – low elements and adventure games

Where participants are spotting they must be instructed and appropriately supervised.

Where a safety system requires a spotter, either the spotter must be:

- a competent spotter or

- under Level 1 or 2 supervision of an activity leader.

The number of spotters required and their location in relation to the climber must be determined prior to the activity for each element or adventure game.

Considerations in determining the number of spotters and their location should include but are not limited to:

- the nature and design of the element or adventure game

- the likelihood of falling and possible directions of the fall

- whether the element has holds on vertical, inclined and/or overhanging surfaces

- the body orientations of the climber that the element or holds permit, or the adventure game requires

- obstacles in the fall zone

- the use of padding to protect from hazards in the fall zone and/or hard landings

- the number of active participants enables activity leaders to monitor, detect and correct improper procedures.

7.5.6 Flying foxes

A full body harness or combination chest and sit harness must be considered when using a flying fox, to mitigate the risk of falling out of a sit harness when inverted.

7.5.7 Giant swings

A full body harness or combination chest and sit harness must be considered when using a giant swing, to mitigate the risk of falling out of a sit harness when inverted.

7.5.8 Rescue systems

Rescue systems must allow for a timely and effective rescue.

Activity leaders

climbing on high elements must carry appropriate rescue equipment to

enable descent to the ground.

7.5.9 Harness hang syndrome

Harness hang syndrome is a medical complication due to being “suspended within a body harness for a prolonged period of time (5 to 30 minutes)” (reference: Australian Resuscitation Council – Guideline 9.1.5 – July 2009). Harness hang syndrome can lead to blood pooling, “shock”, unconsciousness and/or death. It is also known as suspension trauma or suspension syndrome.

Emergency management plans must include:

- rescue of unconscious persons suspended in a harness

- guidance on trigger points for considering the possibility of harness hang syndrome occurring

- appropriate actions to follow where harness hang syndrome is suspected, including but not limited to the relevant first aid treatment.

Also refer to the Core Good Practice Guide – Recognition of competencies. [link]

Glossary

Glossary

Also refer terms and definitions from Core GPG.

AAAS: Australian Adventure Activity Standard

Active Participant: a participant who is either a climber, abseiler, belayer or spotter.

Activity leaders: the collective noun for instructor(s), supervisor(s) and/or manager(s).

Adventure Games (Also known as initiative games): an activity which is not identifiable as a low element or high element activity, but which require spotting to protect a participant if they fall. Activities that do not require spotting are games.

Artificial surface(s): a man-made structure. Also called ‘artificial structures’ and may include but is not limited to portable climbing/abseiling walls, climbing gyms, challenge course elements, fixed climbing/abseiling or other towers, buildings and bridges.

Assisted belay (also known as ‘dynamic belay’ and ‘team belay’): belay system operated by at least one person who is not the climber.

Auto belay: a specialized belay device that operates automatically and removes the need for a belayer.

Auto-locking: a connector that will automatically lock to prevent it from opening and requires two or more deliberate actions to unlock.

Belay line: the line that is used in an assisted belay to connect to the climber.

Belay System: the means by which the climber or abseiler is protected from an uncontrolled fall or descent.

Belayer: a person that operates the belay system.

Bouldering: a form of climbing activity, limited in height and for which fall safety can be achieved by the provision of an impact absorbing system, by a spotter providing control of a fall or by a combination of these measures.

Carabiner: (refer connector).

Climber: the person who is protected by spotting or a belay system.

Competence: ability to apply knowledge and skills to achieve expected results.

Competencies: the plural of competence. Having competence in more than one ability.

Competent leader/participant/person/assessor: someone who has the competence to perform specific functions.

Connector(s): a metal device used to link components together. A connector may be:

- Non-locking: a connector that cannot be locked to prevent it opening

- Self closing: a connector that automatically closes

- Locking: a connector that can be manually locked and unlocked without a tool to reduce the possibility of it opening

- Tool locked: a device that requires a tool to manually lock and unlock. (A maillon is an example of a tool locked connector.)

- Auto-locking: a connector that will automatically lock to prevent it from opening and requires two or more deliberate actions to unlock.

Contact rescue: a rescue requiring an activity leader to manoeuvre to the persons actual location to physically assist them.

Collective belay: a fall from height safety system that operates without a person intervening or operating it. (For example, soft-fall or a pool of water in a fall zone, guardrail, fence etc.)

Continuous belay: belay system that enables climbers to progress from one activity system element to the next and that does not require climbers to undo or change the connection to the belay system.

Continuous self-belay: belay system operated by the climber that enables climbers to progress from one activity system element to the next and that does not require climbers to undo or change the connection to the belay system.

Critical line: a part of an element that a safety system attaches to.

Dynamic belay: refer assisted belay.

Dynamic rope: a specially constructed kernmantle rope that is somewhat elastic under load. The elastic stretch under load is what makes the rope dynamic. (Also see static rope.)

Element: a temporary, mobile or permanent physical structure where a person requires a system to protect them from an uncontrolled fall or descent.

Fall height: The vertical distance between the climbers or abseilers lowest body element and the surface beneath.

Fall factor: is the ratio of the height of a fall (h) (measured before the rope or lanyard begins to stretch) and the rope or lanyard length available to absorb the energy of the fall (L). It is used as a representation of the severity of a fall when arrested by a belay system. It is calculated by (h) divided by (L).

Fall zone: The surface that can be hit by a climber or abseiler falling.

Flash flooding: is flooding in a localised area with a rapid onset, usually as the result of relatively short intense bursts of rainfall.

Flying fox: a means of travel along a sloping rope or wire by attaching to it using a free moving pully and being propelled by gravity.

GPG: Good Practice Guide

High element: (also known as high ropes) is any element or series of elements where the fall height means fall safety requires a belay system using harnesses and specialist safety equipment or other established methods or systems.

Initiative games: See adventure games.

Interlocking device: a belay system using two lanyards that have interconnected carabiners, so that when one carabiner is locked it automatically leads to unlocking the other one and vice-versa.

Level 1, 2 or 3: describes the type of supervision provided to participants. The level meaning is:

- Level 1 – where a nominated person responsible for supervising others during all or part of the activity is able to physically intervene immediately. (Aligns with level 1 in Australian Standard AS 2316.2.2:2016 and direct supervision in the Core GPG).

- Level 2 – where a nominated person responsible for supervising others during all or part of the activity is able to visually see the participant(s) and verbally intervene immediately. (Aligns with level 2 in Australian Standard AS 2316.2.2:2016 and direct supervision in the Core GPG).

- Level 3 – where a nominated person responsible for supervising others during all or part of the activity is in the vicinity and able to respond promptly to provide assistance when called upon. (Aligns with level 3 in Australian Standard AS 2316.2.2:2016 and indirect supervision in the Core GPG).

Level of supervision: a category system that indicates the type of supervision provided to participants. (Refer Level 1, 2 or 3 for the categories used in this GPG.)

Locking: a connector that can be manually locked and unlocked without a tool to reduce the possibility of it opening.

Low element (also known as low ropes or obstacle courses): any element or series of elements where the fall height means fall safety can be achieved by spotting, using an impact absorbing system or by a combination of these measures.

Low obstacle(s): a temporary, mobile or permanent physical structure where a person does not require a system to protect them from an uncontrolled fall or descent. (Also refer low element.)

Minimum Breaking Strength (MBS): is the magnitude of a load that may permanently distort or damage equipment but not cause it to break. (Refer Appendix 3 Equipment load ratings). Equipment should never be loaded to the MBS, even for testing purposes when testing a system before being use, the test should not exceed the safe working load (SWL).

Natural surface(s): the geologic structure and flora that forms a cliff or steep face.

Non-actively participating: a participant that is waiting to but is not currently doing the activity.

Non-locking: a connector that cannot be locked to prevent it opening.

Participant: a person who undertakes an activity and is not a activity leader for the activity.

Responsible person: a competent person who is able to complete delegated elements or tasks during an activity that does not require the activity-specific competence of an activity leader.

Safety Factor: the ratio between the Minimum Breaking Strength (MBS) and Safe Working Load (SWL) to provide a safety margin. It is expressed as a ratio, example 8:1. (Refer Appendix 3 Equipment load ratings).

Safe Working Load (SWL): is the magnitude of load that does not permanently distort, weaken, damage or break equipment and includes a safety margin. (Refer Appendix 3 Equipment load ratings).

Self-belay (also known as static belay): belay system that is operated by the climber.

Self closing: a connector that automatically closes.

Self locking: (see connectors – auto-locking).

Slackline: a type of element formed by a length of flat webbing that is tensioned between two anchors.

Soft-fall: an impact-absorbing surface.

Spotter(s): a person or persons who are spotting.

Spotting: a support process provided by a person, or persons, who offer physical protection of the head and upper body of a person should they fall. (Note: The term “spotting” is sometimes used to describe providing level 2 supervision on high elements. Terms used can vary and providers can use whatever terminology they prefer. In this document note that “spotting” is used to identify situations only as defined. This is to avoid any potential confusion between low element and high element requirements.)

Stated Strength: the magnitude of load that is either the Minimum Breaking Strength (MBS) or Safe Working Load (SWL) marked on equipment or listed in the manufacturers literature. (Refer Appendix 3 Equipment load ratings).

Static belay: see self-belay.

Static rope: a specially constructed low stretch kernmantle rope, that has low elongation under load. The low elongation or stretch under load is what makes the rope static. (Also see dynamic rope.)

Team belay: a type of assisted belay. (Also see assisted belay.)